PEN Film (Polyethylene-naphthalate Film)

Description:

Teonex® PEN Film (Polyethylene-naphthalate Film) is the world's first polyethylene-naphthalate (PEN) film developed and commercialized by Teijin.

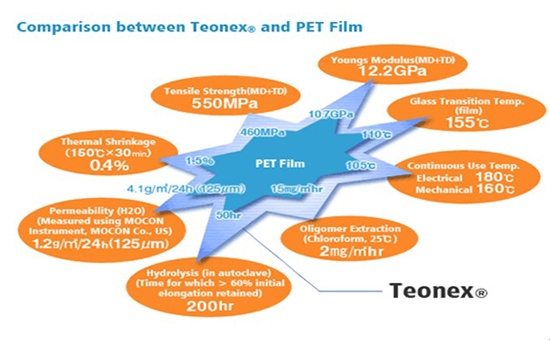

PEN Film has many superior properties such as strength, heat resistance, anti-hydrolysis, dimensional stability, low oligomer extraction, etc.

Application:

PEN Film is used in a wide range of electrical and electronics applications including flat-panel displays, touch panels and dry photo resist, information-related applications, high density data storage tapes, IC card, FPC, and automotive applications. It is also used in electronic components such as capacitors, electric insulation, battery and for optical purposes.

|

Property |

Film

Type |

Colour |

Thickness

(micron) |

Characteristics |

Typical

Applications |

|

Standard |

Q51 |

Clear |

12 to 250 |

Standard grade with good heat resistance and mechanical properties. |

Insulation, Speaker, MTS, Processing film, PV cell |

|

Adhesion |

Q51DW |

Clear |

25 |

Pretreated on both sides for adhesion. |

Insulation, Fuel cell |

|

Low heat shrinkage |

Q81 |

Clear |

25 to 125 |

Very low heat shrinkage type treated by off-line process. |

FPC, RFID |

|

Super low heat shrinkage |

Q83 |

Clear |

25 to 125 |

Extremely low heat shrinkage type treated by off-line process. |

Capability for soldering FPC, RFID, processing film for semiconductor, Flat cable |

|

Good handling performance |

Q02 |

Clear |

Please enquire |

The type that handling performance has better than Q51. |

Insulation, Speaker, MTS, Processing film |

|

Highly transparent,

smooth surface |

Q65F・Q65F£Á |

Clear |

50 to 125 |

Highly transparent and smooth surface for flexible electronics application Excellent heat stability |

OLED, Various TFTs, PV cell |

Properties of Various High Performance Film

|

Property |

Test Method |

Unit |

PEN |

PI |

PEI |

PPS |

PET |

|

Tensile strength |

JIS C-2318 |

MPa |

280 |

280 |

110 |

220 |

230 |

|

Tensile elongation |

JIS C-2318 |

% |

90 |

80 |

80 |

60 |

120 |

|

Continuous use temperature (mechanical) |

UL-746B |

¡ãC |

160 |

200 |

170 |

180 |

105 |

|

Continuous use temperature (electrical) |

UL-746B |

¡ãC |

180 |

240 |

180 |

180 |

105 |

|

Glass transition temperature

(film) |

TDFJ method

by DMA |

¡ãC |

155 |

- |

212 |

90 |

110 |

|

Melting point |

DSC |

¡ãC |

269 |

- |

- |

285 |

258 |

|

Dielectric strength |

JIS C-2318 |

KV/mm |

300 |

280 |

140 |

320 |

280 |

|

Dielectric constant |

JIS C-2318 |

- |

2.9 |

3.3 |

3.2 |

2.8 |

3.1 |

|

Water absorption |

TDFJ method |

% |

0.3 |

1.3 |

0.3 |

0.02 |

0.4 |

|

Density |

JIS C-2151 |

g/cm3 |

1.36 |

1.43 |

1.27 |

1.35 |

1.40 |

|

Flammability |

UL-94 |

|

VTM-2 |

V-0 |

V-0 |

VTM-0 |

VTM-2 |

Roll Size: 3", 6¡± paper or plastic core, ¡Ý6mm width, standard width 1000mm

¡ù Special thickness, length or combinations can be supplied per customer¡¯s request.

Note: Teonex® is a registered trademark of Teijin DuPont Films