|

The series of Benzocyclobutene (BCB) The series of Benzocyclobutene (BCB)

1)Benzocyclobutene

Chemical Abstact Name:Bicyclo[4,2,0]octa-1,3,5-triene

Chemical Name:Benzocyclobutene

CAS Registry No.:〔694-87-1〕

Products classification

|

Products No. |

BCB-1 |

BCB-2 |

BCB-3 |

BCB-4 |

|

Contents |

≥94% |

95%~96% |

96%~97% |

≥97% |

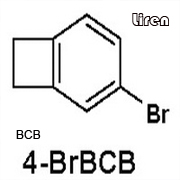

2) The derivatives of 4-bromobenzocyclobutene(4-BrBCB)

4-BrBCB

Chemical Abstract Name:3-Bromo-bicyclo[4,2,0]octa-1,3,5-triene

Chemical Name:4-Bromobenzocyclobutene

CAS Registry No.:〔1073-39-8〕

Products classification

|

Products No. |

4-BrBCB-1 |

4-BrBCB-2 |

4-BrBCB-3 |

4-BrBCB-4 |

|

Contents |

≥94% |

95%~96% |

96%~97% |

≥97% |

4-BrBCB is a very important raw material for preparing many benzocyclobutene monomers and resins.

Other derivatives of BCB

We have developed many useful derivatives of BCB after last several years. They can be used to prepare many kinds of BCB resins. Among them, 4-VSBCB often was used as high performance adhesion promoter. At the same time, we would like to customize the products for client.

3) Benzocyclobutene resins

We have developed a series of thermal cured BCB resins based silicone. They are often used advanced electronic resins and packaging material in microelectronic industry. The resins have a good process procedure and can form film by spinning. The film thickness can vary from 1 μm to 30μm.

Benzocyclobutene resins have low dielectric constants (~2.6), low moisture uptaking, high thermal and chemical stability and high planarity of film.

The main property comparison of BCB resins with other packaging materials

|

Parameter |

Polyimide(PI) |

Benzozyzlobutene(BCB) |

PPQ |

|

Dielectric Constants |

3.5 |

2.6 |

2.7 |

|

Dissipation Factor(1MHz) |

0.002 |

0.0005 |

0.0005 |

|

Volume Resistivity (Ω.cm) |

1016 |

1×1019 |

1×1017 |

|

Moisture uptaking (%) |

0.5-3 |

0.23 |

0.9 |

Applications

1. Multi Chip Modul, MCM

2. Micro Electronicmechanical Systems, MEMS

3. Packaging of Liquid Crystal Device, LCD

4. Polymer film waveguides

Packaging and Storing:

1. At ordinary pressure, the temperature of packaging and storing are lower than 50℃.

2.The packing mode: stainless steel totes (>10 L) or Polytetrafluoroethylene (PTFE) totles(250 mL, 500 mL, 1 L, 2 L, 5 L and 10 L).

|